| Client | KN Energies |

| Project | CCS Baltic PreFEED Study |

| Sector | Energy Infrastructure |

| Services | FEL2 Concept Select & Definition |

| Location | Lithuania & Latvia |

Objective

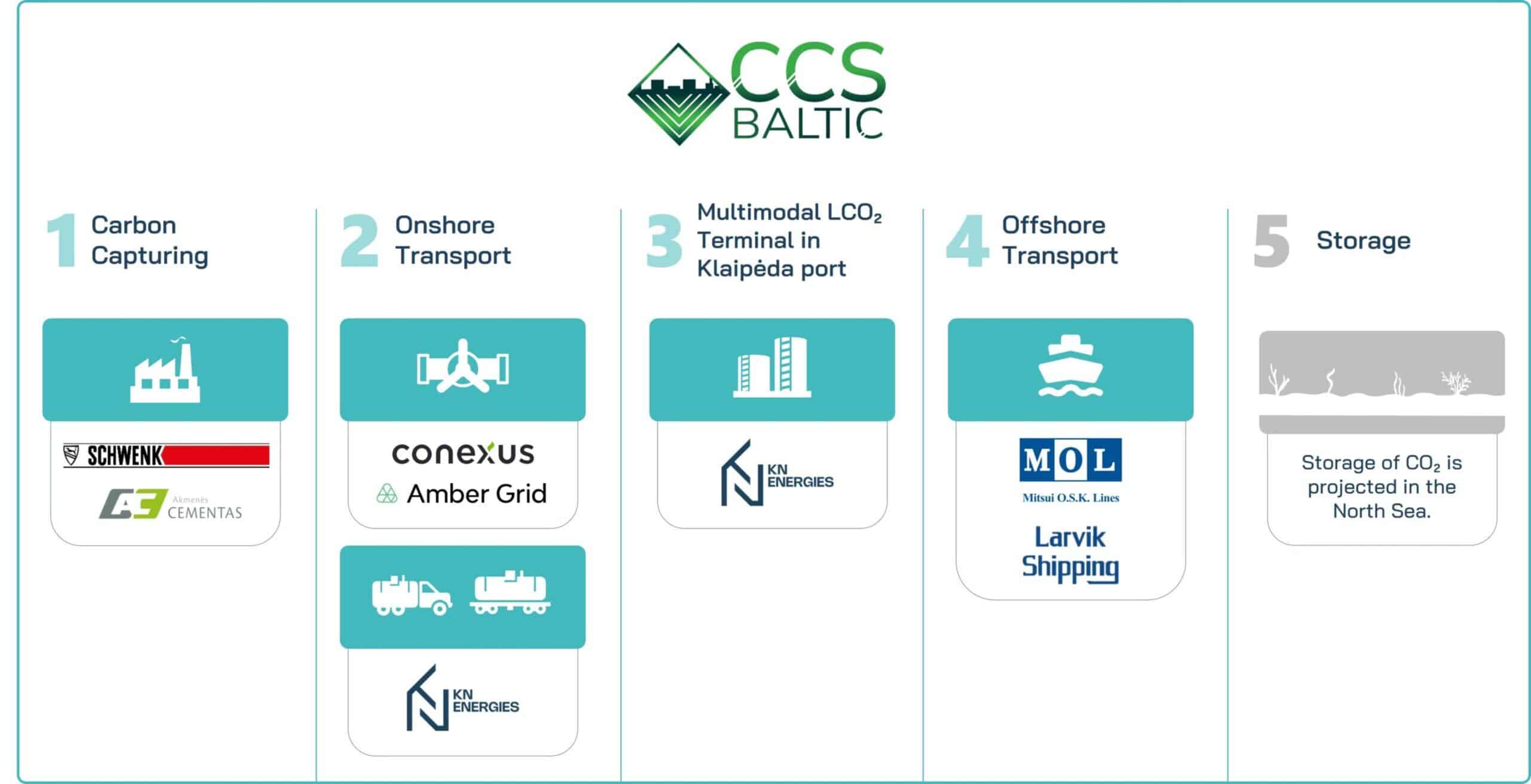

By 2030, the project aims to capture 2-4 million tonnes per annum (mtpa) of CO2 emissions from hard-to-abate industries, transport them to a multimodal terminal, and then ship them offshore for permanent geological storage in the North Sea. The project aims to establish the foundational infrastructure for carbon capture, transport, and offshore storage—positioning CCS Baltic as a critical enabler of the EU’s climate neutrality target by 2050. (image courtesy of the Port of Klaipėda).

The CCS Baltic Consortium engaged io to advance the project definition and increase certainty for the transportation and multimodal terminal elements of the project, enabling the decarbonisation of hard-to-abate industrial sectors in Latvia and Lithuania.

Project Scope

io led a comprehensive concept selection study to identify the optimal onshore CO₂ transportation option and terminal configuration. The io team then completed PreFEED definition on the selected concepts, specifically: study to define the transport and terminal infrastructure, specifically:

- Onshore CO₂ transport from two cement plants—Schwenk Latvija (LV) and Akmenės Cementas (LT)—via rail, road, and dense-phase pipeline.

- Evaluation of multiple transport configurations and sensitivity scenarios to stress-test commercial and technical viability.

- Design of a multimodal CO₂ export terminal at Klaipėda port, including rail/road unloading, pipeline reception, liquefaction, buffer storage (LCO₂), BOG (Boil-Off Gas) recovery, and marine loading.

- Integration of terminal systems with KN Energies’ existing LNG infrastructure.

- Preliminary risk, safety and environmental assessments, along with high-level CAPEX/OPEX estimation.

- Development of a FEED basis of design.

Additionally, io delivered commercial analysis providing a commercial framework comparison, and recommendations for commercial and contractual structure, including a CO2 tariff analysis/tolling tailored to the project.

Findings & Recommendations

Technical Insights

- Integrated Multi-Source Design: The terminal is designed to handle up to 2.8 million tonnes per annum (mtpa) of CO₂ from various emitters and delivery modes. Flexibility is built in to allow for future expansion and operational phasing.

- Smart Rail-Pipeline Balance: A 168 km dense-phase pipeline from Akmenės Cementas offers long-term scalability. For Schwenk, rail logistics are feasible and optimised with dual-track loading, while Klaipėda features single-track unloading with efficient train-turnaround planning.

- BOG System Complexity: Managing diverse operating modes (holding, unloading, ship loading) required dual BOG systems to meet turndown requirements and ensure energy efficiency during variable flow conditions.

- Terminal Configuration: Four spherical storage tanks (37,000 m³ total) and a ship loading jetty capable of handling 20,000 m³ carriers were defined. Key utility and control integration with the existing LNG infrastructure was mapped.

Operational & Safety Considerations

- PreFEED safety studies highlighted that leaks >50mm could pose public safety risks. A detailed Quantitative Risk Assessment (QRA) is essential during FEED.

- Road access, constructability near live infrastructure, and potential conflicts with buried pipelines were flagged as needing careful resolution during FEED.

Commercial & Strategic Considerations

- Sensitivity analysis validated the cost and operational impact of excluding ‘other emitters’ or shifting pipeline transport to rail.

- The phased ramp-up strategy (Schwenk from 2030, Akmenės from 2035) offers investment flexibility but demands robust planning for system redundancy and asset utilisation.

io Value Add

io brought together cross-functional expertise to deliver an integrated and resilient CO₂ value chain design for a first-of-a-kind CCS project in the region:

- Architected a future-ready, multimodal transport and export solution that integrates emitters with marine storage pathways.

- Applied rail logistics modelling and facility simulation to optimise equipment sizing, train loops, and BOG handling under multiple operating scenarios.

- Led terminal layout design within complex brownfield constraints, balancing constructability, operations and future scalability.

- Embedded sustainability and safety from the outset, flagging early design challenges to de-risk future development phases.

- Enabled strategic decision-making through comparative scenario analysis (pipeline vs rail; emitter inclusion/exclusion) to support client investment roadmap.

- Comprehensive benchmarking analysis to evaluate the project against io’s internal database and public domain data.

Through this strategic study, io helped KN Energies take a bold step toward establishing CCS as a viable decarbonisation solution for the Baltic region. Our work delivered not only a technically sound and commercially flexible pathway for future development, but also laid the groundwork for regulatory engagement, stakeholder alignment and investment readiness. The outcome: a de-risked concept and a platform for KN Energies to lead the CCS transition in Northern Europe with confidence.

Following this work, the client secured €3 million in funding from the EU Connecting Europe Facility to progress the FEED.